Empowering organizations to improve productivity, reduce costs, and boost efficiency through cutting-edge Digital Twin, VR, AR, MR, and XR technologies.

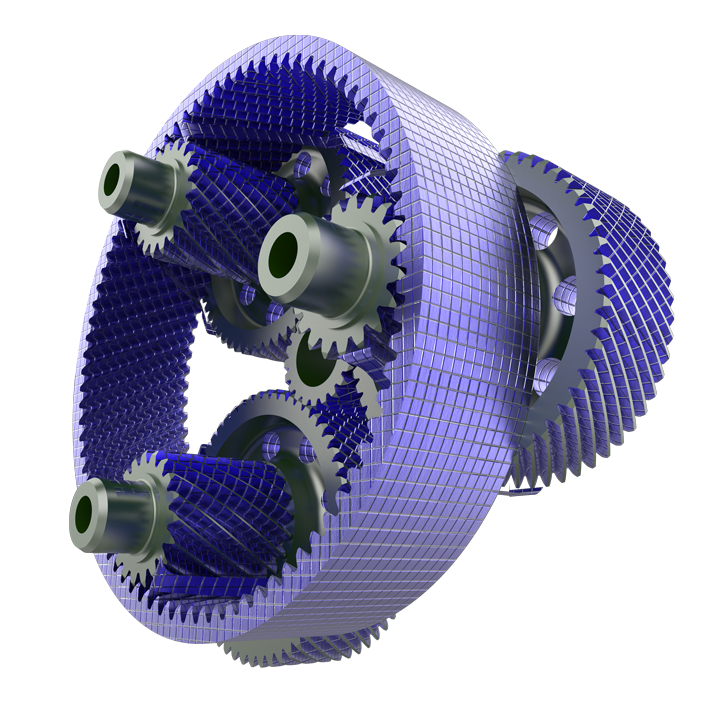

A light virtual comprehensive representation of a mechanical system, created within hours out of a standard CAD. Uses for simulations and eliminates the need for the physical models

A full list of all the parts including metadata and spare parts listing accessible through the Digital Twin. Used for quick parts identification and ordering The Parts Editor enables simple editing and sharing

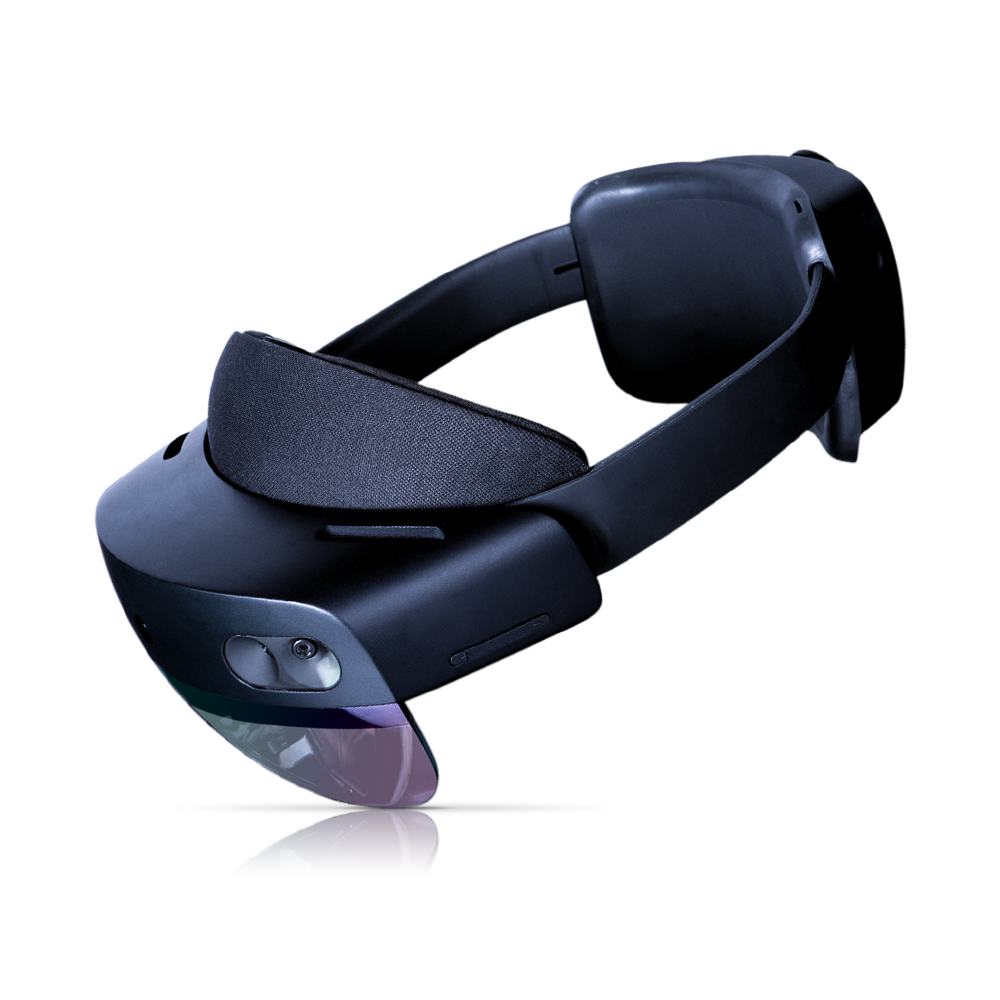

An expert communication that guides the field personnel using AR, MR, video, annotation, and chatting tools. The remote training software saves travel time, improves First Time Fix, and increases Machine Up Time The Remote Support is seamlessly integrated with the Virtual Training Room

Interactive step by steps 3D flows used for training, support, and troubleshooting, Eliminating learning curve, always updated, and performed on any device Flow runs are recorded into frontline.io analytics Flow and procedures creation is done by the Flow Editor and Animation Builder

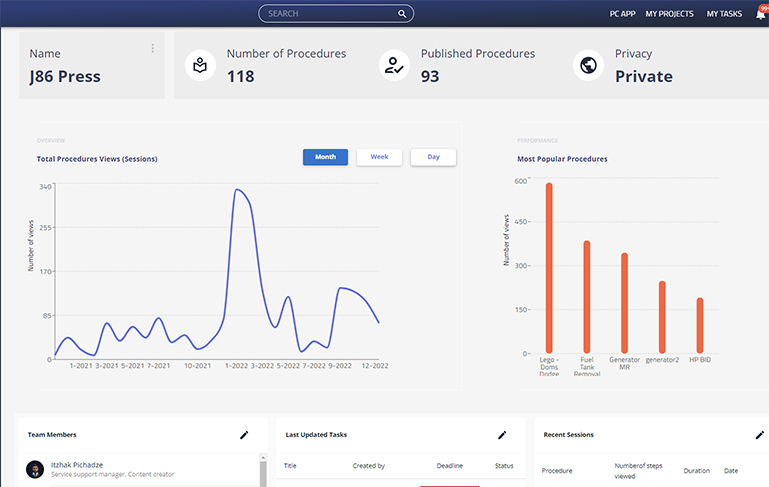

Real-time monitoring and recording of flow and remote assist session, enabling immediate response and continuous improvements process. Including steps performed, the decisions taken, and the user’s feed. The data is compatible with leading AI and BI systems.

Experience by yourself frontline.io. See what a Digital Twin, Interactive Flows, Remote Support, Virtual Training Rooms, Interactive Parts Catalog, and more can do for you

Global brands have trusted us with Xtended reality since 2021

Landa VP of Customer Support

“frontline.io is a game-changer! The unique remote training and support capabilities enabled us to assist customers from a distance – especially during the time of the pandemic. The remote support and the virtual training room are some of its best features. frontline.io is the future.”

Highcon Tier 3 Escalation Engineer

“ Compared to other CAD programs, frontline.io is much easier to use and allows me to support our engineers on the field. As an end-user, frontline.io’s interface makes it easy to create procedures. The 3D parts catalog is undoubtedly one of its best features. “

Sign up for a demo today to get an exclusive look at our unique solution. Don’t worry, we won’t bother you with unwanted messages.